See your 3D models beyond flatscreen and bring geographically dispersed teams together to review designs and accelerate new product innovation.

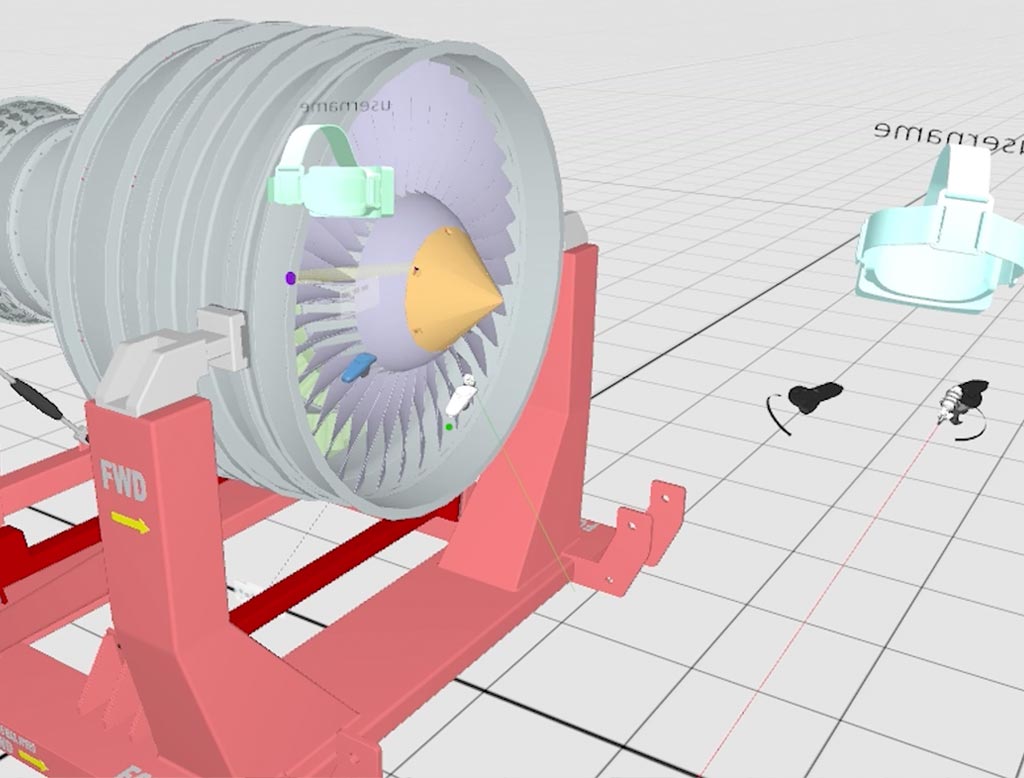

The Masters of Pie market-proven data-agnostic XR collaboration solution is ideal for Engineering applications as it brings people and complex real-time data together. The same Radical software framework is able to support a broad range of solutions for product design, robotic simulation and planning.

Over 70% of product costs are a direct consequence of decisions made during the design process. The immersive design review solution from Masters of Pie turn product design into a more intuitive and collaborative process by integrating the Radical SDK into your CAD/PLM software application. This deep level of integration allows designers to leverage XR tools with one click and no data export or preparation to review the 3D model in VR or AR instantly.

All the underlying features from the CAD/PLM software application are available to be used in the VR or AR session, enabling designers to see models beyond 1:1 scale. Finally, the ability to bring designers and stakeholders together into earlier discussions leveraging XR collaboration will ultimately reduce errors, fast track the handover to manufacturing and improve the time to market.

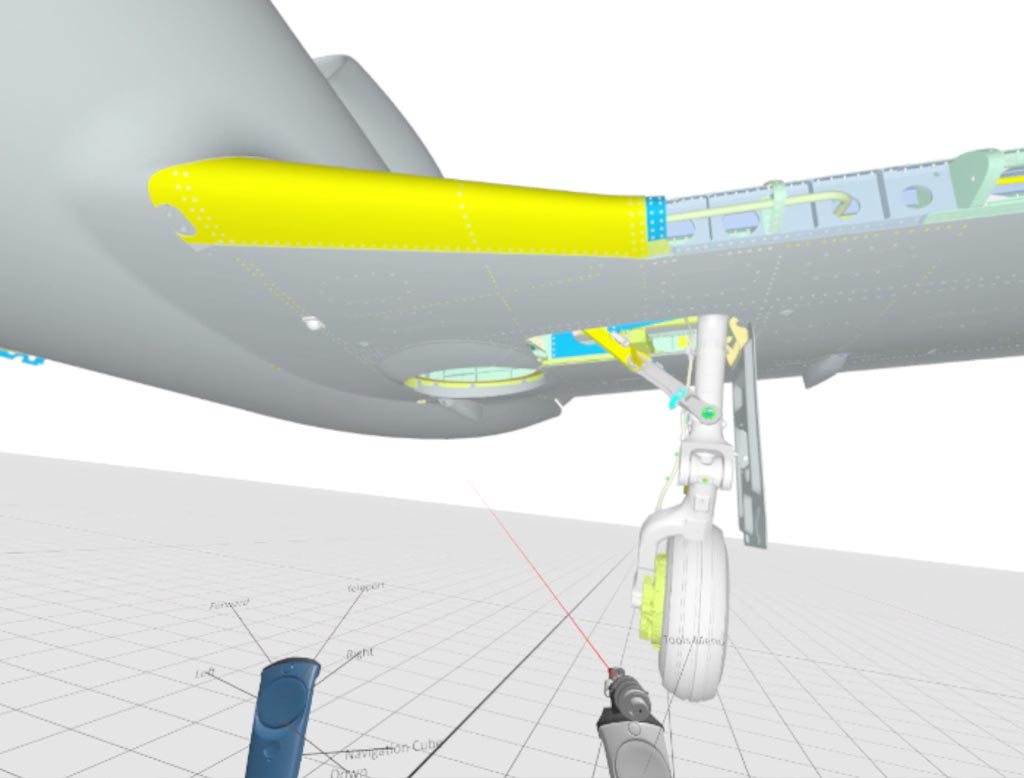

The combination of 5G enabled VR headsets and the Masters of Pie digital thread solution creates a flexible environment between engineering and manufacturing teams, independent of where they are located to synchronise design reviews and shorten the new product introduction process.

Hosein Torabmostaedi - Digital & Innovation Manager at Unipart

Explore 1:1 scale model changes dynamically in AR for a more powerful understanding of your edits as you make changes and updates. The experience is driven entirely by the existing CAD user interface with no extra interactivity required.

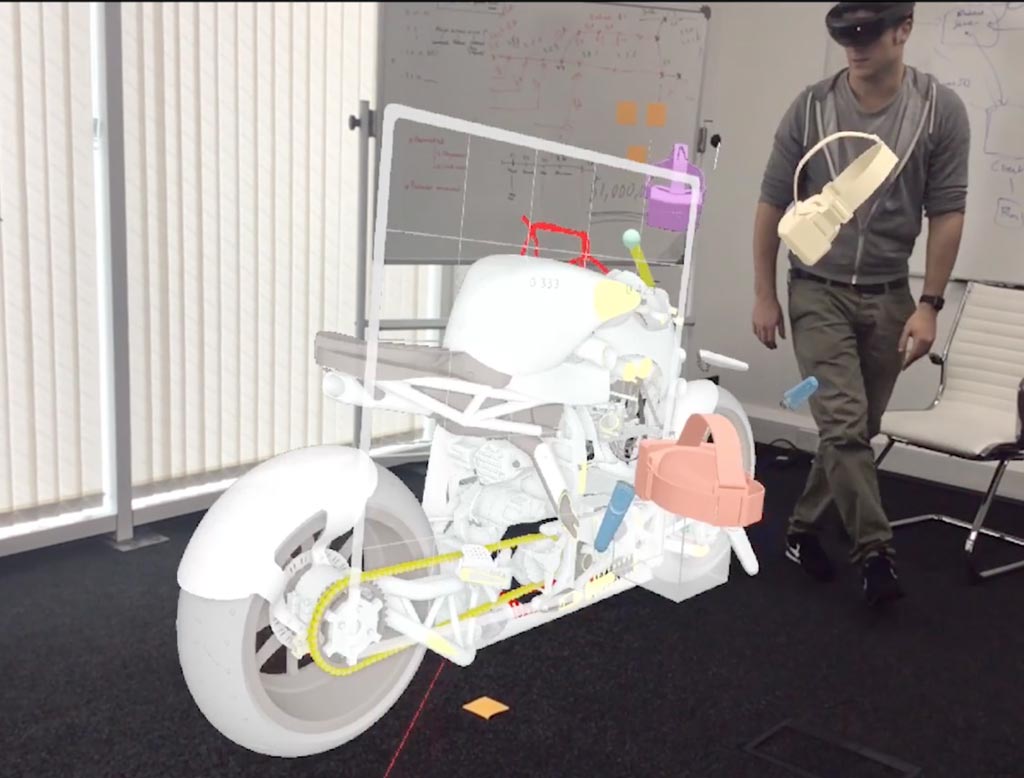

The ability to conduct factory planning and production simulations by using the digital twin allows manufacturers to fail in software before deploying to the real world. The bi-directionality leveraged by Radical allows plant operators to adjust machinery and robotic performance in real-time, with the ability to load a full factory digital twin.

Bring remote experts and complex 2D and 3D data together to diagnose issues, support maintenance processes, and train teams in the field on complex procedures.

Find more about Radical and how you can unlock immersive collaboration.