Deliver XR Solutions to the factory floor

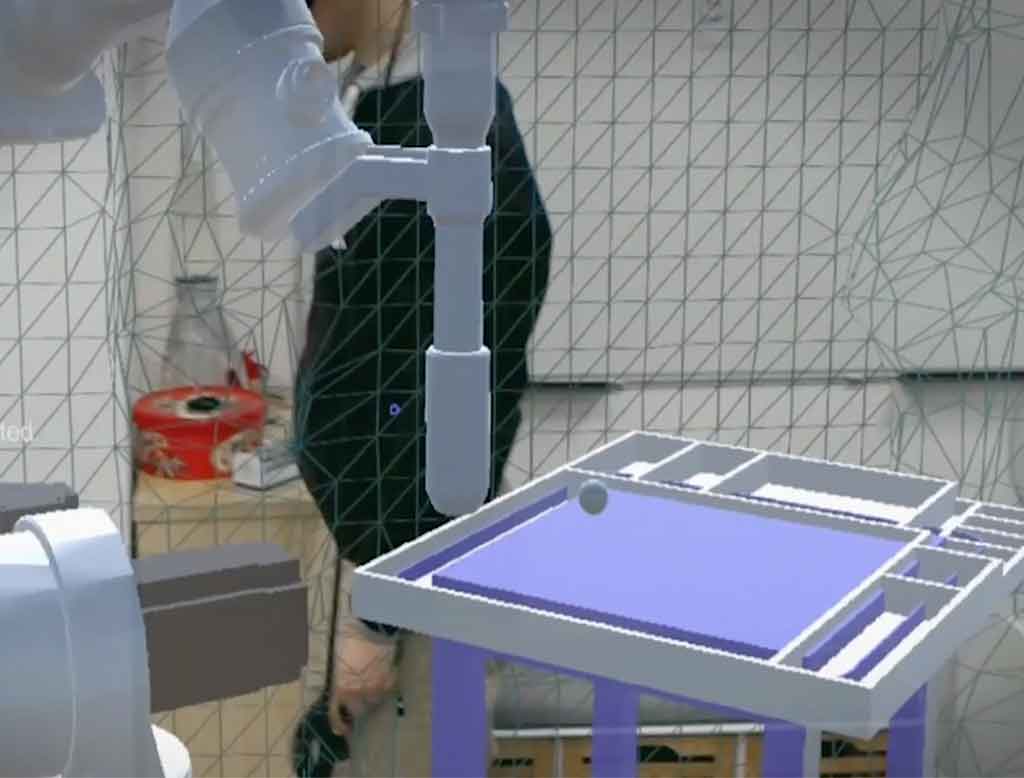

Create XR Collaboration workflows that bring together remote experts, field workforce, and enriched digital twins combining 3D and contextual data from industrial streams to improve product assembly, equipment maintenance, layout simulation, and create a path for smart manufacturing.